what is a galvanic isolator?

When you connect your boat to a marina electrical supply you also connect your boat to all the other boats in the marina via the earth connection in your shore power mains lead. This creates a pathway for small electrical currents to flow from one boat to another. Unfortunately this pathway leads to increased corrosion of the underwater metals and results in rapid loss of anodes and increased pitting and deterioration of hulls, propellers, shafts, outdrives etc. We can protect against this problem by installing a galvanic isolator.

So how does it work?

A galvanic isolator is inserted into the earth line of the shore power lead. This can be done internally in the boat or by using our plug in waterproof units. You simply unplug the shore power lead from your boat, plug the lead into the isolator and re-insert the isolator flying lead back into the shore power inlet. Job done! The isolator now creates a block for damaging galvanic currents minimising the risk of corrosion. In the event of an electrical fault onboard the isolator senses the fault condition and ensures your trips and rcd protection operate as normal ensuring safety onboard.

If the earth cable causes the problem why not just remove it?

The earth cable is essential for safety. In the event of an electrical fault onboard the earth wire ensures the rcd / fuses/ breakers operate correctly and disconnect the mains electrical supply until the fault is rectified.

How easy is it to fit an isolator?

Internally fitted units are inserted into the incoming earth line between the shore power inlet socket on the boat and the consumer/distribution unit onboard. This is done by locating the incoming shore power lead, cutting the earth cable at a convenient point and inserting the isolator using terminal connectors provided. The live and neutral cables of the shore power lead remain untouched. We supply excellent instructions and diagrams but if you do not feel competent to proceed we would recommend our “Plug and play” units. These units plug into the shore power leads either at the boat or the shore power pedestal of the marina. No electrical knowledge needed… Just 30 seconds to install!

15 amps, 30 amps, 70 amps, 100 amps? What does it mean?

A question we are asked all the time. Basically the amperage rating of the isolator is the amount of current the isolator can handle under severe fault conditions. The isolator must be able to handle more than the available current supplied to the boat. Usually UK marina supplies are either 16 or 32 amps so the isolator must be able safely handle at least 20% more than the maximum current available to comply with legislation. Realistically the higher the rating the more reliable the isolator.

What is the purpose of status monitoring?

Units with status monitoring measure the current flowing through the isolator. If the current flow increases beyond a preset threshold led’s will illuminate to indicate a fault condition. Safeshore models with monitoring also offer increased galvanic protection and easy testing of the installation.

How reliable are your isolators?

Safeshore have now been supplying the marine industry for over 20 years. Our reliability record is superb reflected by our lifetime warranty on all products.

What is the difference between galvanic and stray current corrosion?

Galvanic corrosion is caused by the interaction of differing metals whilst connected together and in contact with the water. Stray current corrosion is caused by poor electrical connections, poor wiring in contact with bilge water and “leaky” power supplies. These currents are often transmitted down the shore power earth wire. A galvanic isolator will help to block both galvanic and stray current corrosion.

Which isolator do you recommend?

If you intend DIY installation model GI 70sm or GI 70smi both offer maximum protection, easy testing and fault monitoring. Model GI 70sm has remote monitoring so if you plan to fit under the floor this allows the monitor to be installed remotely on the dashboard. Model GI 70smi has internal monitoring so if fitting the isolator in an easily viewable position this is the one to use. For “Belt and braces” reliability models GI 100sm or GI 100smi are the upgraded versions.

Plug and play isolators 30 seconds to install!

We supply two plug and play easyfit units:

safeshore galvanic isolatorGI 70 inline is a standard protection isolator for use with blue type shore power plugs utilised by UK/EU marinas.

safeshore galvanic isolatorGI 70 inline is a standard protection isolator for use with blue type shore power plugs utilised by UK/EU marinas.

safeshore marine galvanic isolatorGI 70smi inline offers advanced protection, easy testing and fault monitoring.

Special products: We supply upgraded versions of the inline units specifically designed for use with 32 amp commercial power supplies. These units are fitted with 100 amp internal isolator and heavy duty cables / large blue 32 amp plug and socket. Please phone for details.

Quick check: Not sure which supply you have? Simply measure across the diameter of the plug with exposed pins:

32 amps = 56mm......(16 amps = 43mm)

Over 24,000 UK boats are now protected by Safeshore galvanic isolators!

20 years of professional service.

Tried, trusted, reliable quality with lifetime warranty.

Safeshore supply isolators for every vessel... D.I.Y. internal fitting or easy fit plug-in units, offering maximum protection, total reliability and superb customer service.

Guaranteed protection from both galvanic and highly destructive stray current corrosion.

Trade supply : Generous trade discounts available. Request our trade price list.

Call: 01977 513 607; Write:email; Visit: website

what is an anode?

what is an anode? do I need anodes?

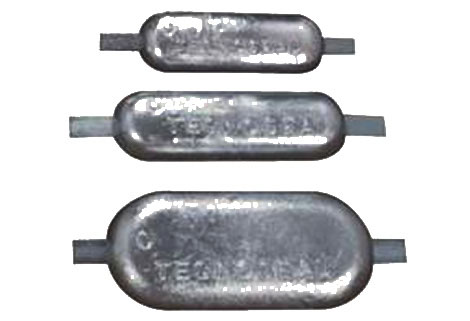

do I need anodes? choosing your anodes

choosing your anodes Anodes Direct provide anodes of various materials to commercial and leisure craft throughout the UK and Europe. We specialise in providing marine anodes sourced only from the best manufacturers including Tecnoseal, MME, MG Duff, UK Anodes, Performance Metals, Piranha, Vetus, Side Power, Gori, Bruntons & Darglow. Zinc for Sea Water, Aluminium for Brackish Water, Magnesium for Fresh Water. We are always ready to advise and help, so do get in touch!

Anodes Direct provide anodes of various materials to commercial and leisure craft throughout the UK and Europe. We specialise in providing marine anodes sourced only from the best manufacturers including Tecnoseal, MME, MG Duff, UK Anodes, Performance Metals, Piranha, Vetus, Side Power, Gori, Bruntons & Darglow. Zinc for Sea Water, Aluminium for Brackish Water, Magnesium for Fresh Water. We are always ready to advise and help, so do get in touch! RCR managing director, Stephanie Horton, advises: “The key to dealing with our increasingly extreme weather conditions is timing and balancing health and safety. In order to stop a vessel drifting onto land when water levels rise, position a scaffold pole or poles, or a boarding plank, between the boat and the river/canalside edge and fix it into position. This acts as a mooring post, preventing flood waters from floating the boat onto land.

RCR managing director, Stephanie Horton, advises: “The key to dealing with our increasingly extreme weather conditions is timing and balancing health and safety. In order to stop a vessel drifting onto land when water levels rise, position a scaffold pole or poles, or a boarding plank, between the boat and the river/canalside edge and fix it into position. This acts as a mooring post, preventing flood waters from floating the boat onto land. “If the boat has drifted, it’s all about timing; when the water levels start to go down, try to push the boat back into the water or off the land before they drop too far. But be cautious as this can be dangerous, particularly if you’re unable to see under the water.

“If the boat has drifted, it’s all about timing; when the water levels start to go down, try to push the boat back into the water or off the land before they drop too far. But be cautious as this can be dangerous, particularly if you’re unable to see under the water. So, what goes through our minds as we literally watch paint dry?

So, what goes through our minds as we literally watch paint dry? 'BMM' is a small business; just myself (with the help of 'Morgan' the dog, my Lurcher), my Wife Francoise assists with the website, Frans, Aubrey, Bob, Carl and Adrian are all part-time, freelance instructors with Bob acting as equipment manager and helping me run the jobs and training we offer.

'BMM' is a small business; just myself (with the help of 'Morgan' the dog, my Lurcher), my Wife Francoise assists with the website, Frans, Aubrey, Bob, Carl and Adrian are all part-time, freelance instructors with Bob acting as equipment manager and helping me run the jobs and training we offer. The 'Leisure' industry on the canals and rivers in the UK is a hugely well catered for sector: the commercial side of things was an untapped market. 'BMM' are filling this gap with a range of services that was otherwise untouched.

The 'Leisure' industry on the canals and rivers in the UK is a hugely well catered for sector: the commercial side of things was an untapped market. 'BMM' are filling this gap with a range of services that was otherwise untouched. An employer / organisation / trust putting personnel near the water's edge; 'should the risk of accidental immersion have been shown in the risk assessment' are obliged to provide water safety awareness and APPE (Aquatic Personal Protective Equipment) training to their personnel. Particularly relevant should those personnel 'be managing groups'.

An employer / organisation / trust putting personnel near the water's edge; 'should the risk of accidental immersion have been shown in the risk assessment' are obliged to provide water safety awareness and APPE (Aquatic Personal Protective Equipment) training to their personnel. Particularly relevant should those personnel 'be managing groups'. Having worked as an MCA BoatMaster commercially since the 1990's and many years as a safety & rescue boat operator and rescue technician the evidence was seen on regular basis to show that professional commercial training was needed for the canal and river environment. That was

Having worked as an MCA BoatMaster commercially since the 1990's and many years as a safety & rescue boat operator and rescue technician the evidence was seen on regular basis to show that professional commercial training was needed for the canal and river environment. That was  Initially we began running 'commercially orientated' skipper training aboard a commercial vessel. Many folks that have undertaken a boat handling licence did so on a 'holiday hire' type vessel or a standard narrowboat. This is ideal for 'leisure' boating but does not train the candidate in commercial handling, for example all the manoeuvres and control needs to be from the stern rather than crewed from the bows - no access through on commercial vessels when loaded.

Initially we began running 'commercially orientated' skipper training aboard a commercial vessel. Many folks that have undertaken a boat handling licence did so on a 'holiday hire' type vessel or a standard narrowboat. This is ideal for 'leisure' boating but does not train the candidate in commercial handling, for example all the manoeuvres and control needs to be from the stern rather than crewed from the bows - no access through on commercial vessels when loaded. We then branched out to water safety awareness then rescue training via the Royal Life Saving Society: for employers we provide the 'National Water Safety Management Programme' and Outreach Rescue 'Water Rescue Awareness' and Water Rescue First Responder' training. For those personnel without a statutory duty to respond we also run a short course; the 'Water Rescue Equipment Training' course developed again by the RLSS.

We then branched out to water safety awareness then rescue training via the Royal Life Saving Society: for employers we provide the 'National Water Safety Management Programme' and Outreach Rescue 'Water Rescue Awareness' and Water Rescue First Responder' training. For those personnel without a statutory duty to respond we also run a short course; the 'Water Rescue Equipment Training' course developed again by the RLSS. Next we commenced training Powerboat operators intending upon a career in the marine rescue sector - RYA Powerboat Level 2 and Outreach Rescue 'Powered Boat for Rescue Response' - ensuring that safety boat teams working on contracts on the inland waterways have a comprehensive background in ensuring their clients safety. This is something that needs to be acted upon as the accepted industry standard is a very basic qualification and leaves room for accidents, injuries and fatalities.

Next we commenced training Powerboat operators intending upon a career in the marine rescue sector - RYA Powerboat Level 2 and Outreach Rescue 'Powered Boat for Rescue Response' - ensuring that safety boat teams working on contracts on the inland waterways have a comprehensive background in ensuring their clients safety. This is something that needs to be acted upon as the accepted industry standard is a very basic qualification and leaves room for accidents, injuries and fatalities. RYA, RLSS, Outreach Rescue & MCA Training Centre Principal; Gailey Wharf Training Centre.

RYA, RLSS, Outreach Rescue & MCA Training Centre Principal; Gailey Wharf Training Centre. Precision control at your fingertips, you command as little or as much power as needed!

Precision control at your fingertips, you command as little or as much power as needed! Both the owner and his employees were very impressed with the system.

Both the owner and his employees were very impressed with the system.

For more than 50 years, VETUS has been an internationally operating developer, manufacturer and trading company, selling marine engines, generators and technical equipment for recreational craft and small commercial vessels.

For more than 50 years, VETUS has been an internationally operating developer, manufacturer and trading company, selling marine engines, generators and technical equipment for recreational craft and small commercial vessels. No other product illustrates this versatility more than their groundbreaking environmentally friendly toilet fluid Blue Bio. Launched at a time when 99% of the leisure industry used formaldehyde or glutaraldehyde based products that simply preserve waste until it can be off loaded at a suitable processing station to be treated as hazardous waste, Blue Bio was a game changer.

No other product illustrates this versatility more than their groundbreaking environmentally friendly toilet fluid Blue Bio. Launched at a time when 99% of the leisure industry used formaldehyde or glutaraldehyde based products that simply preserve waste until it can be off loaded at a suitable processing station to be treated as hazardous waste, Blue Bio was a game changer. Taking this on board, we developed a prototype clear version which Linda kindly set about testing, finding it to be the perfect product for use in toilet tanks within all their boats. Linda told us “all boaters that have trialled this new Clear Blue Bio have reported that it successfully cleans the toilet as well as getting rid of all bad odours, with the improved fragrance of the fluid also being very well received”.

Taking this on board, we developed a prototype clear version which Linda kindly set about testing, finding it to be the perfect product for use in toilet tanks within all their boats. Linda told us “all boaters that have trialled this new Clear Blue Bio have reported that it successfully cleans the toilet as well as getting rid of all bad odours, with the improved fragrance of the fluid also being very well received”.

RCR managing director, Stephanie Horton, comments: “Fuel problems are mainly caused by diesel bug and contaminated water. Diesel bug is an enzyme that lives off water in the diesel, either appearing as black dust/ soot or a black slime/jelly. Once in the system it clogs the engine’s fuel arteries and stops the engine working. Mild cases will respond to a fluid ‘Marine 16’; it prevents bacterial growth and kills anything that may be forming in the tank. More severe cases require a diesel bug shock treatment. Dirt and debris can also block filters and contaminate fuel so check and service regularly.

RCR managing director, Stephanie Horton, comments: “Fuel problems are mainly caused by diesel bug and contaminated water. Diesel bug is an enzyme that lives off water in the diesel, either appearing as black dust/ soot or a black slime/jelly. Once in the system it clogs the engine’s fuel arteries and stops the engine working. Mild cases will respond to a fluid ‘Marine 16’; it prevents bacterial growth and kills anything that may be forming in the tank. More severe cases require a diesel bug shock treatment. Dirt and debris can also block filters and contaminate fuel so check and service regularly. “General wear and tear is the main cause of gear box and drive plate failure, so regularly service the gear box. When hitting an underwater object, it may affect the drive plate, but not necessarily the gear box. With a fouled propeller, loss of propulsion is commonly due to the prop being covered in debris such as weed or leaves. Clear by putting the engine into reverse.

“General wear and tear is the main cause of gear box and drive plate failure, so regularly service the gear box. When hitting an underwater object, it may affect the drive plate, but not necessarily the gear box. With a fouled propeller, loss of propulsion is commonly due to the prop being covered in debris such as weed or leaves. Clear by putting the engine into reverse.

To find out more about River Canal Rescue go to their

To find out more about River Canal Rescue go to their